When it comes to grain moisture content, many farmers feel the pinch of the Goldilocks effect. Too wet, and your grain is moisture-discounted at sale. Too dry, and you lose weight from shrinkage – also a profit drain.

Fortunately, in an industry where a lot of challenges are out of farmers’ control – weather, trade policy, commodities prices to name a few – there are still some things you can control.

One of those is managing your stored grain. Doing it properly could be the tipping point between profits and loss.

And squeezing out profits has never been more important. U.S. farmers now hold a mere 30% share of the global grain trade. These days an international farm economy presents increasing competition. More countries are not only growing crops for themselves, but for export too.

To make matters worse, the country’s grain production is at an all-time high. U.S. farmers have more stored grain than ever before. So, it’s easy to see how grain management directly impacts farm security.

Smart decisions can have a big impact on the bottom line.

So how do farmers get that “just right” grain moisture content that maximizes profits?

Grain Moisture Content That Is Too Wet, Too Dry, Just Right

What happens when grain is too wet or too dry?

Grain that is too wet when stored is at high risk for rapid deterioration and spoilage. Grain that’s too dry is subject to damage during handling. That makes it more susceptible to insects and molds during storage. Shrinkage also results when grain is too dry.

The first thing to recognize is that stored grain moisture content is not an absolute. There are guidelines that you’ll want to consider. For example, stored corn has an optimum moisture content of under 15% on average, and for soybeans it’s 13%. But that’s if you’re planning to use it by summer.

Acceptable percentages of moisture content for stored grain drop depending on your goals. Consider if you plan to take it to market in June, or store it up to a year or more. The longer you store your grain, the lower the moisture content should be. Corn stored over a year should have a moisture content of no more than 13%. For soybeans the number drops to 11%. Storing low quality grain drops the percentages even further.

Delivering your stored grain to market at the optimum moisture content yields the best return on your investment.

Are you getting the best ROI on your stored grain? Monitoring your grain’s temperature will keep it in optimum condition and yield the best prices. Ask us about grain temperature monitoring, live chat with us, or call us at 1 800 438 8367.

Pre-storage Grain Drying

Pre-storage grain drying is a necessity for wet grains. For example, optimum moisture content for harvesting corn without mechanical damage is 22%. But optimum moisture content for stored corn is 14% or lower.

High-temperature dryers can speed up drying time for wet grain and are energy efficient. But the exchange is possible cracking and damage from overdrying, and raising the grain temperature too high for storage. Using a dryeration bin to cool grain after drying and before storing can help.

Batch-in-bin drying is another option, but it can leave dried grain with temperature and moisture variations throughout. A stirring device is helpful in drying grain more uniformly.

Grain moisture content must be no more than 21% to begin with before being dried in bin with natural or low-temperature air. There is also a limit to how much you can accomplish with natural air drying before mid-November when it’s no longer efficient to dry.

Each harvest season will require new decisions.

Bin Grain Drying

Theoretically, the focus for bin drying grain should be on cooling the grain with aeration. Drying happens naturally as the grain cools. If initial grain moisture content is too high, all the aeration and monitoring in the world won’t keep spoilage away.

However, dry grain cooled to the proper temperature should keep grain at the same moisture content. This is called Equilibrium Moisture Content. It is when the combined temperature and relative humidity of the bin are neither losing nor gaining moisture.

As every farmer knows though, grain may not stay dry, even though it was properly dried prior to storage. There may be bin wall, roof, and vent leaks to contend with, or forgotten open hatches. You have to monitor and respond to all condensation in the bin, localized grain moisture content, and moisture migration.

Monitoring Grain Moisture Content

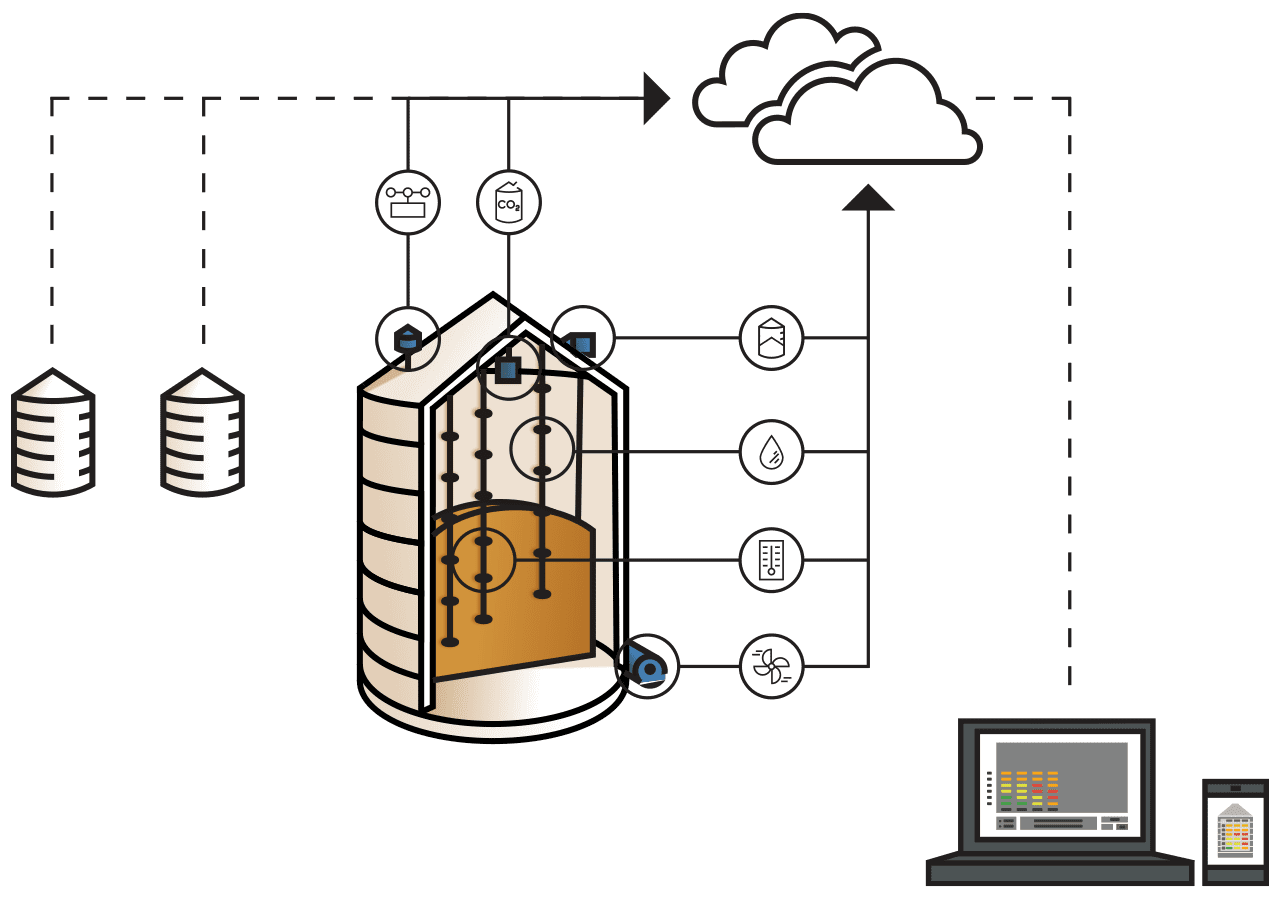

Grain temperature is the key factor in successful grain storage. But, grain moisture is also an important factor to consider in preventing grain spoilage. It’s easy to see the symbiotic relationship, since temperature and air flow control moisture content.

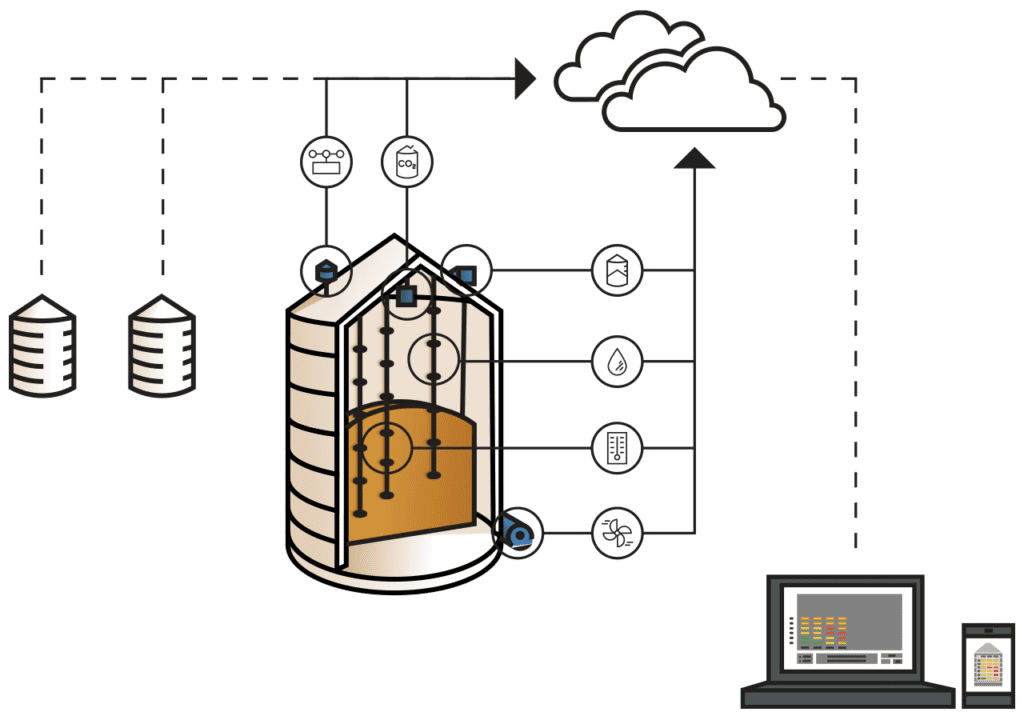

Temperature, grain moisture content, and relative humidity determine your grain’s quality. A moisture cable has a temperature sensor as well as a relative humidity sensor. You put the two readings into a calculation that gives you an approximate moisture number.

You can scale the system up or down to suit your farm needs. Monitor anywhere from a few small bins to large operations with numerous, and sometimes faraway, bins. You can also monitor sensor cables remotely from your home office. Actually, you can do it from any location in the world where cell phone service is available.

You can’t know what’s going on inside your grain bins until signs of heat and spoilage are obvious. You can either guess, or use technology that provides accurate data. Which would you rather base your decisions on?

A grain temperature and moisture monitoring system is a management tool. It can give you peace of mind, help you reach your goals, and get the best ROI possible. There’s no need to let grain moisture content throw a wet blanket on your profits.

Get peace of mind knowing your grain is in optimum condition. Ask us about grain temperature monitoring, live chat with us, or call us at 1 800 438 8367.