Soybean numbers just keep growing. By the end of 2019, the U.S. Department of Agriculture expects the country’s soybean inventory to hit 910 million bushels, nearly double the amount available in 2018. That data highlights an already growing issue for farmers. A larger inventory means more storage space. Monitoring all that grain increases concerns about grain bin safety.

Protect Grain Quality

I understand how hard it can be to find the time to check your grain each week. Driving or walking from silo to silo just adds more work to an already loaded schedule. At the same time, you can’t just walk away and ignore it. After all, the higher the quality of your grain, the better the price.

While you can’t improve the quality of grain after the harvest, you can protect it from deteriorating. That’s done by controlling the temperature.

Now yes, I know some of you still think this is debatable. You argue that you need to check your grain in person. You believe it’s the only way to spot signs of mold or mildew. But how do you do that? By smelling the grain.

Guess what. If you can smell the deterioration, it’s already too late. Grain bins are too big for that to work anymore, plus was it ever that effective? Temperature cables would’ve given you accurate information before spoilage was bad enough to cause odor. You could’ve headed off the problem before it started.

But there are a few other factors to consider besides preserving grain quality – your primary asset. There are also the issue of grain bin safety and related costs.

Improve Grain Bin Safety

The safest time to climb into your grain bin is never.

I talk about grain entrapment in a previous post titled, Buried Alive: 20 Seconds to Total Grain Entrapment. It actually only takes four seconds to get trapped in flowing grain, according to the National Agriculture Safety Database. If you don’t get out within 20 seconds, you can be completely covered.

While that might seem like something from a TV drama, it actually happens more often than you think. More than 100 farmers are killed each year while walking across the grain surface, according to the NASD.

Let’s say you walk in and notice some spoiled grain in one part of the silo. What you don’t see, however, is the air pocket right beneath it. If you fall through that crust of spoiled grain, you can end up trapped as the void quickly gets filled.

The NASD gives a cautionary example of a transport driver who was buried in an avalanche of grain earlier this year. He had tried to check on a bin from the inside when a void collapsed. Even without entrapment, asphyxiation inside a grain bin can occur from poor ventilation. It’s one of the top five farm hazards, and it’s no joke.

If you monitor grain in person, you have to go out to the bin site regardless of weather conditions. If it’s a cold December day with snow on the ground, you’ve still got to walk out to the silo. The same goes for a stormy day in July, when rain is pouring down and there’s lightning all around.

In poor weather conditions, you can slip and get injured. Falls are also among the top five farm hazards. Sometimes you may have to go to the top of the bin or silo. But remember, an outside fall from that height is typically fatal. Wet or icy rungs on a bin ladder can also cause you to slip and fall. Just breaking a bone can put you out of commission for your other farming duties.

Avoid the High Cost of Ignoring Grain Bin Safety

Let’s say you get injured while out checking a silo. The problem stretches beyond your physical health. If the injury is serious, you’ll have to pay medical bills, as well as weigh the possibility of having to hire replacement workers. After all, someone has to monitor the grain while you’re recovering, as well as work in the field on this year’s crop.

We already looked at how difficult it can be to keep your farm in the black. The 2018 Farm Production Expenditures Report from the U.S. Department of Agriculture, paints a rough picture. From 2016 to 2018, expenses for American farmers rose from $346.9 billion to $359.8 billion.

Agriculture economists at Iowa State University show that for corn alone, production costs have climbed from $3.53 per bushel in 2007 to nearly $5 in 2018. Soybean costs also spiked, going from $6.73 in 2007 to $10.67 per bushel in 2018.

For a farmer already dealing with these extra costs, any additional medical or employee related expenses won’t help balance that out.

Discover the Benefits of Remote Grain Monitoring

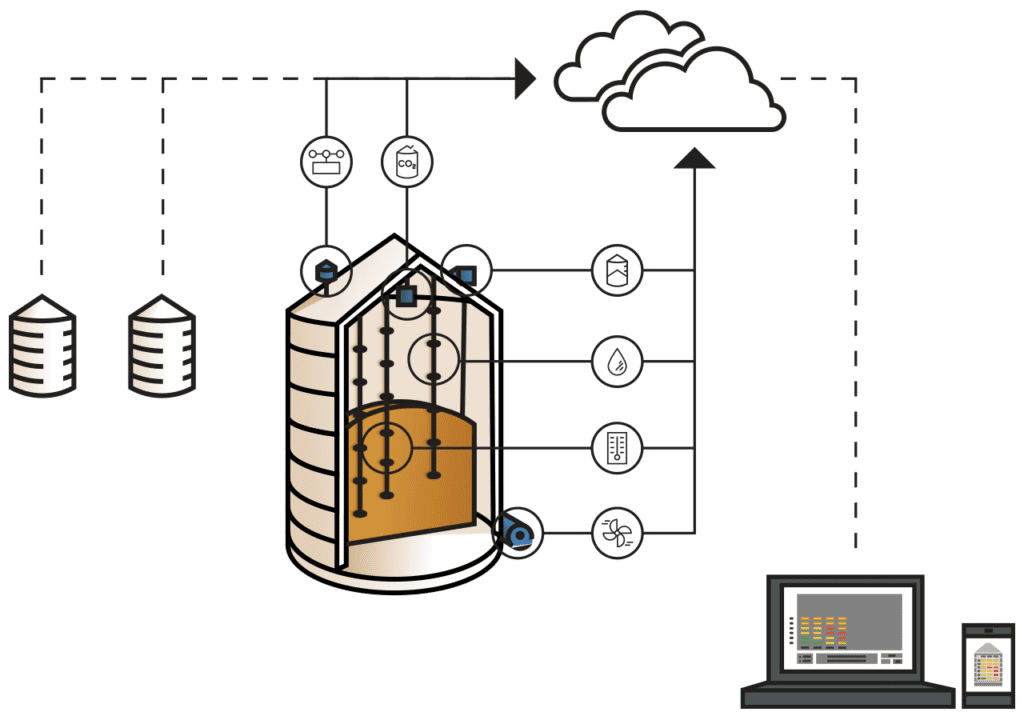

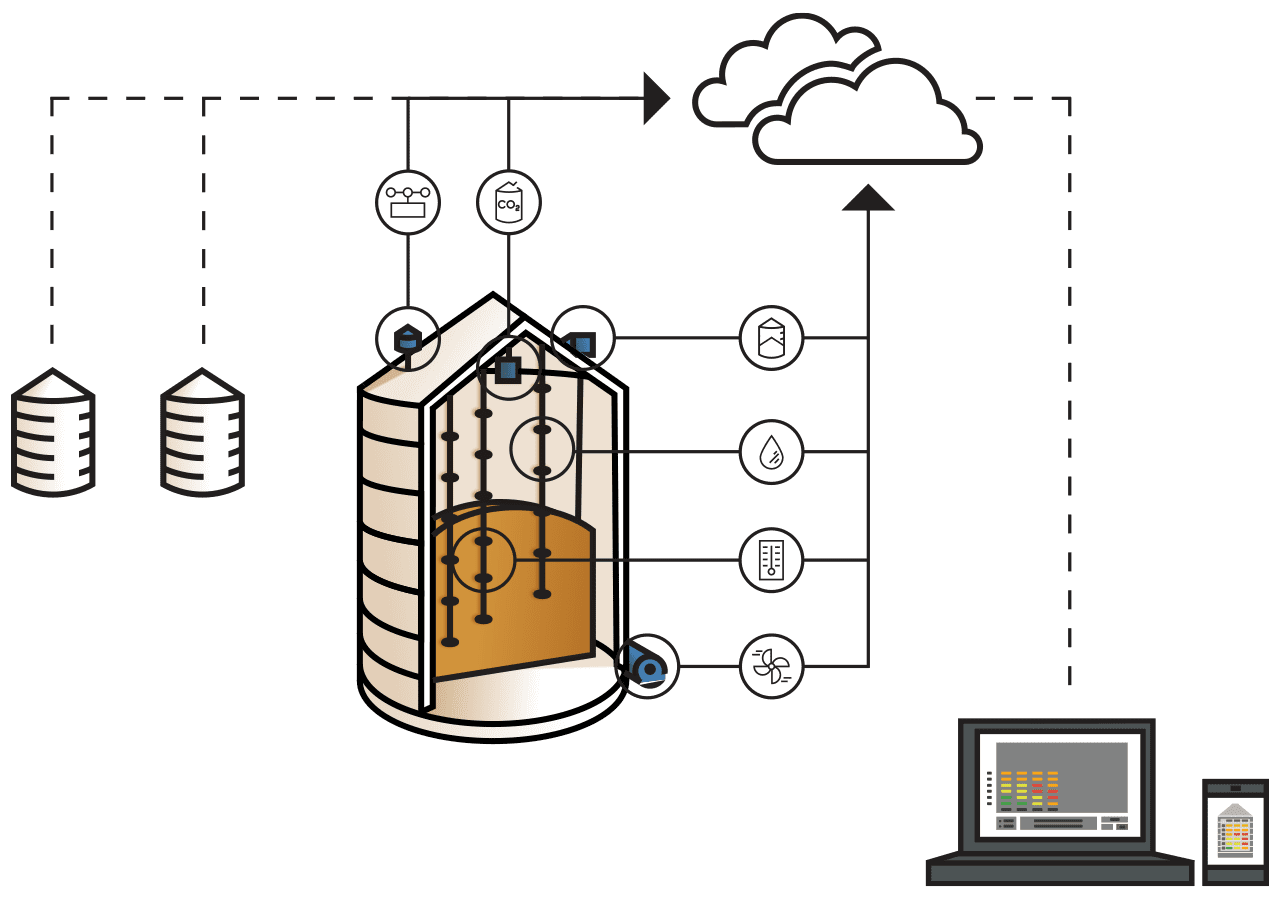

A better option is to check on your grain remotely. Temperature cables are set up inside your grain bins. They collect data from each of your storage bins and send it to a sensor board. When the sensor board gets the data, it’s sent to a server. You can then use a smartphone or computer to log in at any point and see the data.

If it’s snowing outside, you can just grab your phone and see the grain temperatures. You don’t have to try to walk or drive in bad weather. You also minimize common safety risks at your bin sites with remote grain monitoring.

The remote system also provides data from previous weeks and months to compare. You can monitor changes in grain condition with historical data. Also, knowing the temperature in real time can help you prevent grain shrinkage. You’ll know when to turn fans on or off, preventing over-aeration in the silo.

What You Can Do Today

You can find more information about grain bin safety, and how remote monitoring can keep you, your family, and your grain managers safer. Isn’t it better to plan for the safety of all your farm workers now, than to have to explain why you didn’t after a tragedy?

Talk to one of our remote grain monitoring experts to develop a secure grain storage strategy for your on-farm storage needs.

Call us at 800 438 8367, contact us here, or live chat with us to ask about the right grain temperature monitoring system for your new or existing on-farm storage facilities.

Join over 20,000 other farmers who follow us on Facebook where we discuss a variety of farming topics including agribusiness, agritech, and grain temperature monitoring.