Tri-States Grain Conditioning General Manager, Dan Winkowitsch, examines the tale of the grain bin moisture cable.

You may be asking yourself why an agri-tech product designed with grain farmers in mind is a fairy tale. So let’s take a look at moisture cables – where they originated, what they are, and why they don’t measure up to the hype.

The Origin of the Moisture Cable

Where did the idea of a moisture cable that measures the moisture content of your grain come from anyway? For years, people have monitored the temperature of their grain. And they know that if the temperature inside the grain mass remains stable, the grain remains stable.

Eventually, along came the moisture cable. Where did it come from, and why? The moisture cable developed out of a wish. The wish of many farmers and grain managers was, I wish I knew the moisture content of my stored grain.

As this desire was expressed again and again, someone realized that what farmers wanted actually created a new market opportunity. If there’s demand, after all, then the market opportunity was in supplying the product that filled the demand. And so they developed a product, and called it a moisture cable.

The Emperor’s New Clothes

You may remember another fairy tale written by Hans Christian Andersen, a nineteenth-century Danish author. It’s called “The Emperor’s New Clothes.” In the tale, two weavers promise the emperor an extraordinary new suit of clothes. They tell him that it’s invisible to people not suited for their position, incompetent, or stupid. Only they don’t really make any clothes, but rather convince everyone that the clothes are invisible only to the half-witted.

Although no one sees the clothes, they won’t admit to it fearing they’ll be unmasked as stupid or incompetent. Finally, a young child says to the crowd, “But he isn’t wearing anything at all!”

The truth was that the emperor had no clothes on.

And there’s no such thing as a moisture cable.

The Truth about Moisture Cables

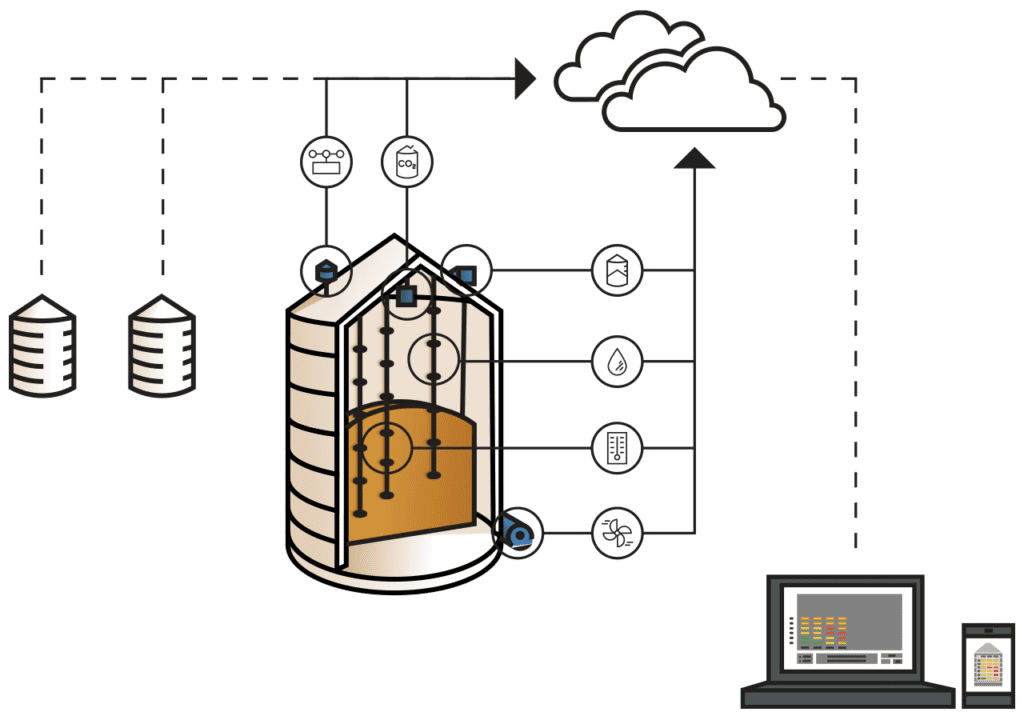

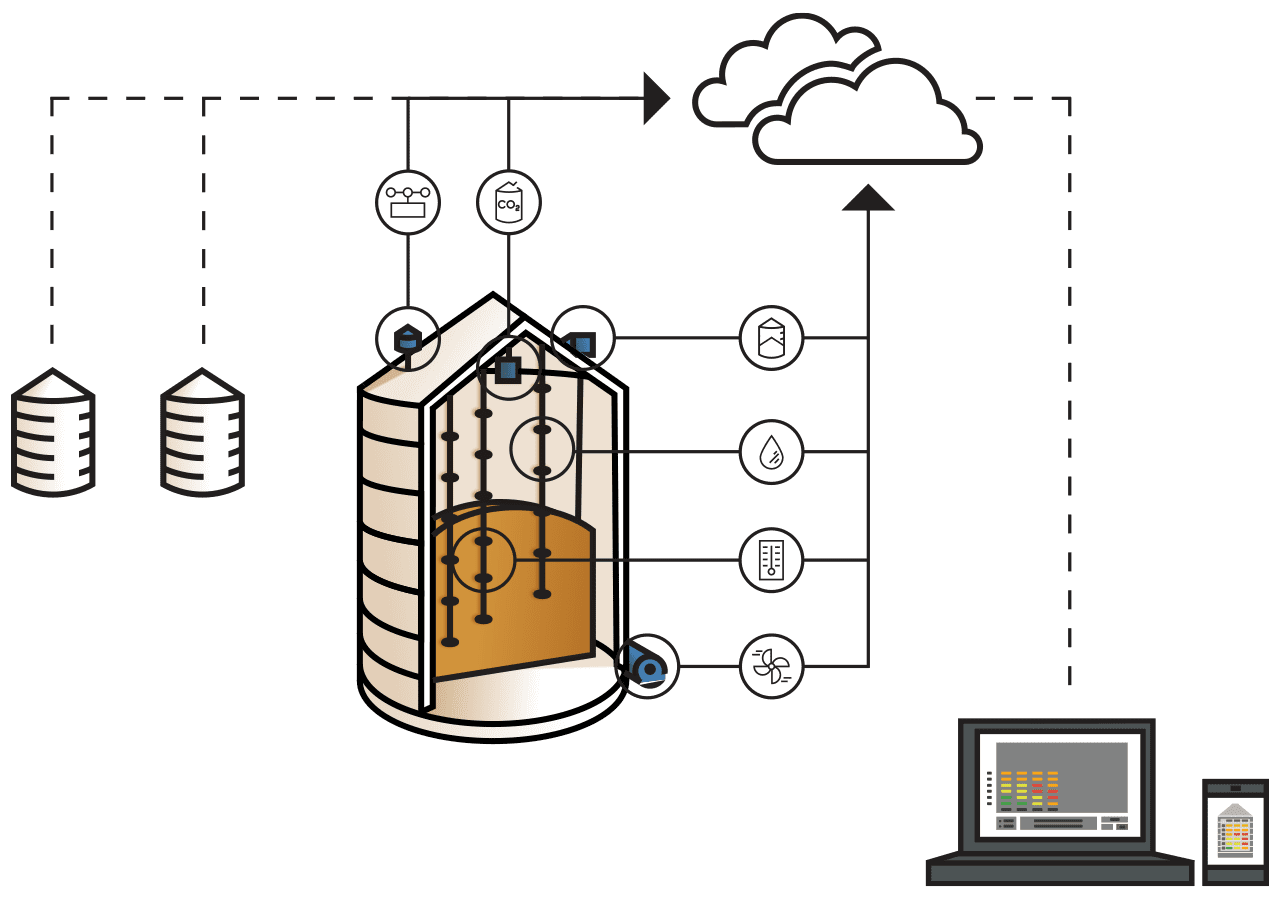

There is a cable that has two sensors in it. One sensor is a temperature monitoring sensor. And the other measures the relative humidity of the air surrounding the kernels of grain in the bin. This then has to be hooked to a computer with software that takes in both of those pieces of information. The program and some algorithms then use the data to give you a calculated estimate of the moisture content of grain stored in that bin.

Sounds great, right? Well, there are a few problems to be aware of with moisture cables.

Common Moisture Cable Problems

First, it can only measure what it touches. So, if you have a large bin, you’re going to need a lot of moisture cables. Otherwise, you only know what the moisture might be in the spot where the cable is located.

Next, it tells you what you already know. These days, there aren’t many grain farmers or managers that put grain in a bin before knowing its moisture content. The moisture content of grain is a critical factor in determining how long the grain can be stored.

Naturally, people will be sure to know this before storing grain. The combine itself gives farmers a reading of the grain’s moisture content before it’s ever stored. Growers test the moisture content of grain before and after drying to get to the optimum moisture level for storage.

Elevator managers, on-farm grain managers, and farmers know their crops’ moisture levels prior to storage. So that’s a known quantity. Then we know that if the temperature in the bin remains stable, the moisture content will also remain stable.

Finally, it’s rather expensive to put moisture cables in your bin, which you probably know if you’ve tried pricing them.

But they sell.

Stored Grain ‘Happily Ever After’

Now you know the tale of the moisture cable. It’s a relative humidity sensor and a temperature sensor in one cable. But, it may not do everything it was presented to do.

Instead of purchasing expensive moisture cables that give you information you already have, why not stick to affordable temperature cables? You can expect to pay an average three cents per bushel for one year based on bin capacity. They’re all you’ll ever need to keep your stored grain in top condition for sale.

Think about it. Do the same thing – keep stored grain in prime condition – for less. Who wouldn’t want to do that?

Headquartered in America’s Heartland, we have an extensive network of contractors in 40 countries. Call one of our grain temperature monitoring solution specialists for a free quote. They’re ready to help you choose the temperature monitoring device best suited to your operation, and to provide the tech support you need.

Ask us about options here, live chat with us here, or call us at 1 800 438 8367.

Follow us on Facebook where we discuss a variety of farming topics, including grain temperature monitoring and Smart Farming.