Just how important is it to know your grain temperature? Turns out, what you don’t know can hurt you.

Scrolling through some past visitor comments on our Facebook page, we came across this unsolicited comment:

“Wow, who could have known TSGC would have evolved so much since working for my uncle Waldo (Rich) in his basement and garage in ’82 on the first temp cables! One of our favorite stories was from a co-op in [a nearby Minnesota town]. They did not want cables in their bean silos and 6 months later, they were jackhammering out thousands of bushels of “baked beans.” Congratulations on all your success through awesome products and customer service!!”

That got us reminiscing about the many stories we’ve collected over the years at TSGC. This one from our early days stands out as memorable because of its consequences. One of our salespeople contacted a nearby elevator about our grain temperature monitoring equipment. It was pretty new technology at the time. The owner scoffed at the idea and didn’t buy, and the rest is history.

According to General Manager, Daniel Winkowitsch, this is what happened to their grain.

“The soybeans heated up in their bin and rotted, and then they turned into something that looks like baked beans. However, they are fused together. And although you usually don’t actually use a jackhammer, you wish you had one to get them out. The point being if you had cables and didn’t let your beans heat up, you would never have to face that horrible situation.”

Agri-technology and Farming

Farming is an industry steeped in tradition. Many of those who farm are proud to tell you how long their family has been farming the same land. It’s because every farmer knows of the challenges their families have faced. They know the struggles they’ve overcome, and how they’ve managed to persevere through it all.

Change is also a fundamental component of farming, especially over the last few decades. Of course, change doesn’t negate the wisdom of tradition or history, but it does require forward thinking and the acceptance of new agri-technologies.

Embracing new tools to improve productivity and efficiency can mean the difference between thriving and going under. And dismissing technology out of hand can lead to unnecessary consequences like those suffered by the folks in Minnesota.

Grain Temperature Monitoring

As most farmers know, fighting against natural elements in order to grow a plentiful crop is only half the battle. You need to be able to take advantage of the markets. But monitoring and maintaining grain stored after harvest in piles, silos, and flat storage warehouses creates an entirely new challenge. There are numerous factors to consider, but many of them are related to knowing your grain’s temperature.

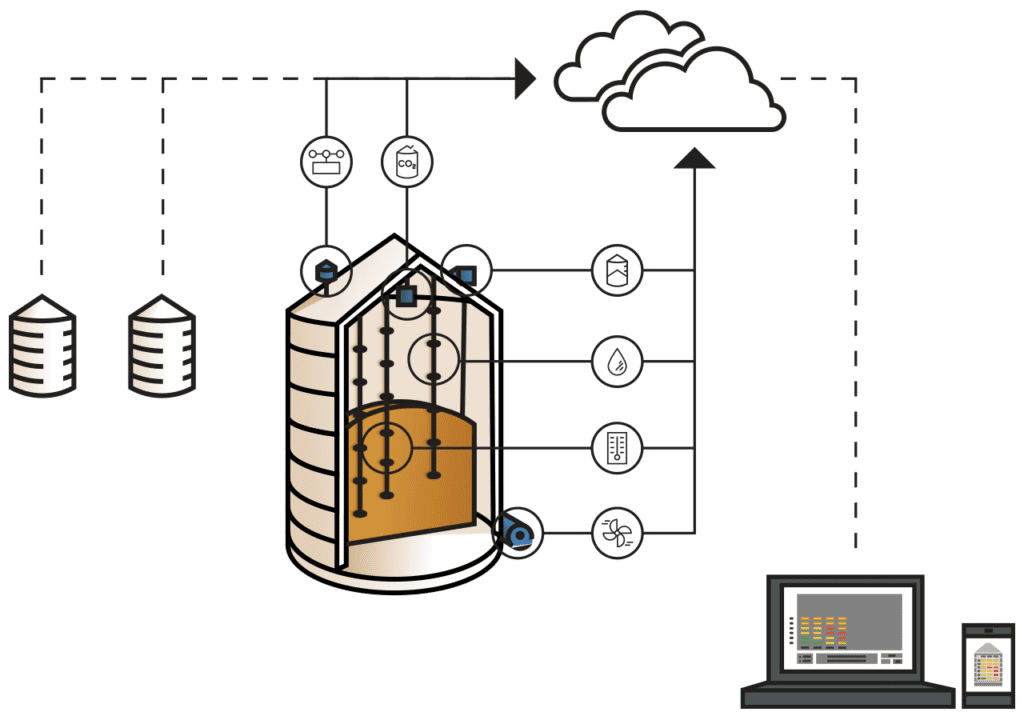

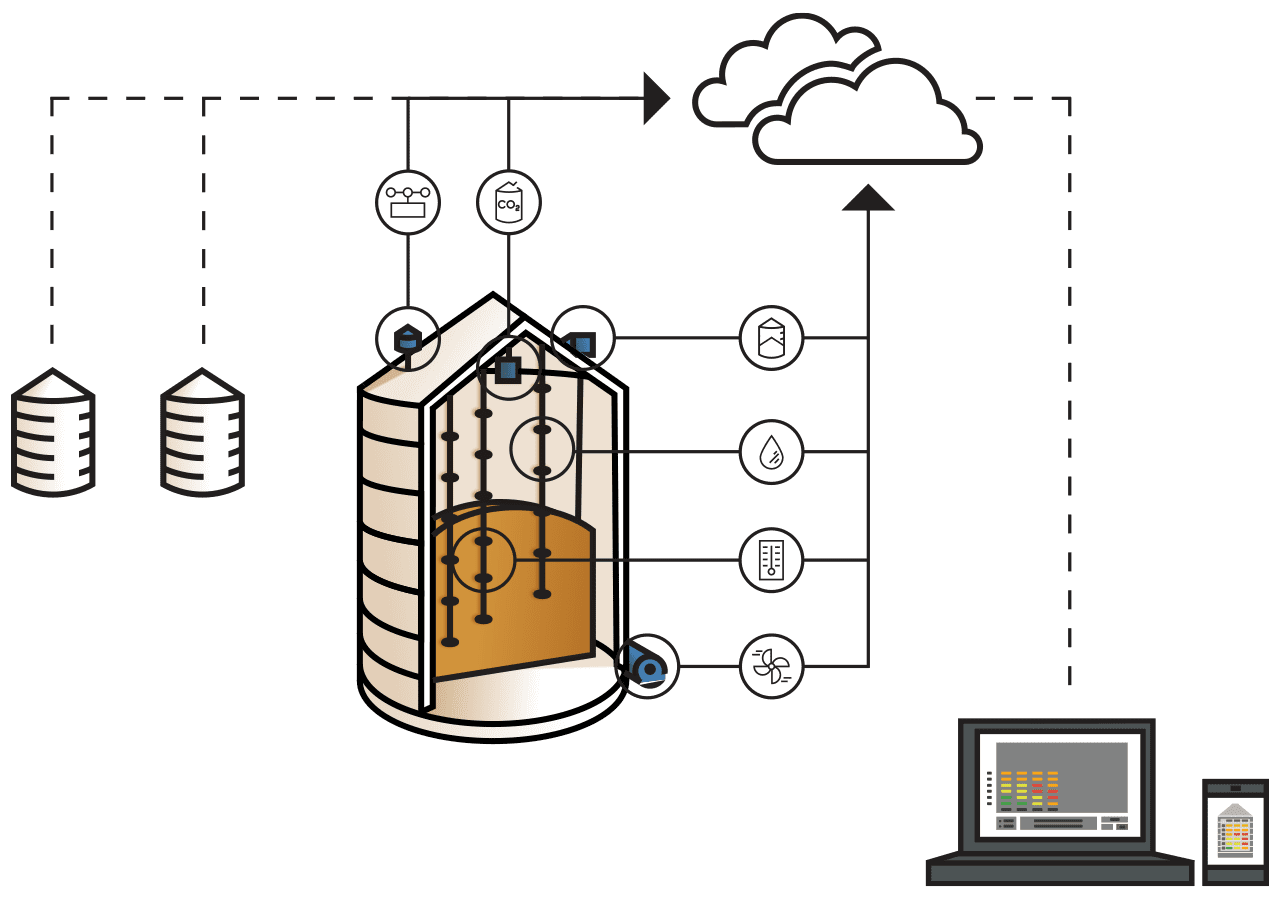

It doesn’t matter if you’re a small farm operation or a commercial grain storage facility. Grain temperature cables are the most reliable way to protect your grain investments. These systems continually track stored grain conditions and alert you when the conditions alter or fall outside of acceptable boundaries. They ensure you have the information needed to keep your grain storage environment stable. This prevents unwanted growth within the silos and prevents spoilage.

The reward to you is avoiding serious losses. Knowing grain temperature leaves you with a superior product, and provides you a higher return on your investment.

Benefits of Knowing Grain Temperatures

The difficulty in maintaining a crop’s value after harvest has been a long-running one. In the past, it relied heavily on guesswork and gut instinct. Many farmers’ intuitions were spot on. But, there would be times when the mark would be missed leading to post-harvest spoilage and insect infestation.

This was especially true in times when conditions were less than ideal at harvest. Sometimes grain didn’t have the appropriate time to dry before needing to be stored. In the current grain market, you can’t lose even a single grain bin to these effects. It can greatly impact your farm’s financial health.

Thankfully technology has grown at a swift rate making high-tech advancements that include grain temperature cables. The cables are equipped with sensors that monitor grain for previously undetectable hot spots.

The collected data is used to minimize guesswork allowing you to make data-based decisions. You can then take informed actions like turning on or off aeration fans, fumigating, or selling.

Temperature monitoring cables aide in the prevention of shrinkage from overdrying, which in turn prevents profits from shrinking as well.

The convenience of remote monitoring with some of these systems provides you with the freedom you need. That enables you to focus attention on other parts of your operation.

Grain Temperature Monitoring Detects Problems Early

If you rely on the ‘sniff test’ to check your grain quality, by the time you can smell it, it’s too late.

Grain temperature monitoring cables eliminate the estimation and uncertainty of stored grain quality. The cables are suspended from the roof of the grain bin. Sensors that are spaced apart along the cables monitor the temperature of grain.

The height of the bin determines the cable length. Sensors in the cable are typically spaced between six to eight feet apart. The number of sensors per cable is determined by its length. Each sensor in the cable records temperatures ensuring potential hot spots are easier to detect.

These more precise readings give you the chance to act fast. You can make the best possible decisions in order to protect your harvest.

Knowing your grain temperature makes it possible for you to know when to run the fans. This way you’re not running them needlessly. It saves money on utilities, and takes the guesswork out of knowing your grain condition. You’ll always be a step ahead, bringing good quality grain at maximum weight to market for the greatest profit.

Call Now for More Information

712 336 0199

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and smart farming.