Grain temperature monitoring has become the norm, rather than the exception, but why? New market circumstances and weather changes are driving new grain storage rules.

The grain started piling up last fall. By the end of 2018, the U.S. Department of Agriculture reported 14.8 billion bushels of corn and 4.7 billion bushels of soybeans had been harvested. That added up to the largest soybean crop in U.S. history and the second largest corn crop.

This comes after a half dozen strong harvests, which had already pushed supplies beyond the current demand on the market.

Instead of preparing to sell grain within months, some farmers have been forced to focus on long-term storage. How do you keep grain stored that long and make sure it doesn’t rot? That’s one of several questions highlighting how the rules for storing grain are changing.

Why Is There a Grain Surplus?

We currently have a unique situation. After six strong harvests, the grain supply far outweighs the demand. That means a good portion of the 2018 crop will have to be stored for at least a year.

Why is the supply piling up? Part of that comes from market conditions. As trade negotiations continue between the U.S. and China, export orders declined in 2018. Also, U.S. farmers face new competition, as the EU, Russia and the Ukraine all are exporting grains.

To cut back on a 2020 U.S. crop surplus, the Senate Committee on Agriculture is pushing for more Conservation Reserve Program sign-ups, so that enrolled acres can be removed from production.

Temperature is Key to Quality

In order to maintain the quality of the crop for long-term storage, we have to pay close attention to grain moisture and air temperature. “More dried grain goes out of condition because grain temperatures are not controlled than for any other reason,” according to a 2018 report from Purdue University’s Cooperative Extension Service.

With grain, quality is key. The higher the quality, the better the price when you’re ready to sell. Now, you can’t improve the quality of your grain after the harvest. At this point, it’s fully mature. But you can protect grain from deteriorating by controlling the temperature. If the air temperature isn’t controlled, moisture can build up and cause the grain to spoil. We have advisers standing by to walk you through grain temperature control, so contact us now.

How does temperature monitoring make a difference? Let’s say you brought in a corn harvest with 17 percent moisture content. According to the USDA Farm Service Agency’s data, you could store that corn at 80 degrees for an estimated 27 days. That means you would need to find a buyer within a month, before fungus or mold sets in.

But as we mentioned before, that’s just not possible right now. You’ll be lucky if you sell the new crop within a year, so 27 days really doesn’t help much.

Now let’s take that same corn but lower the air temperature in the silo to 40 degrees. With nothing but the change in temperature, that corn can be stored for approximately 282 days. You now have more than nine months to sell the product.

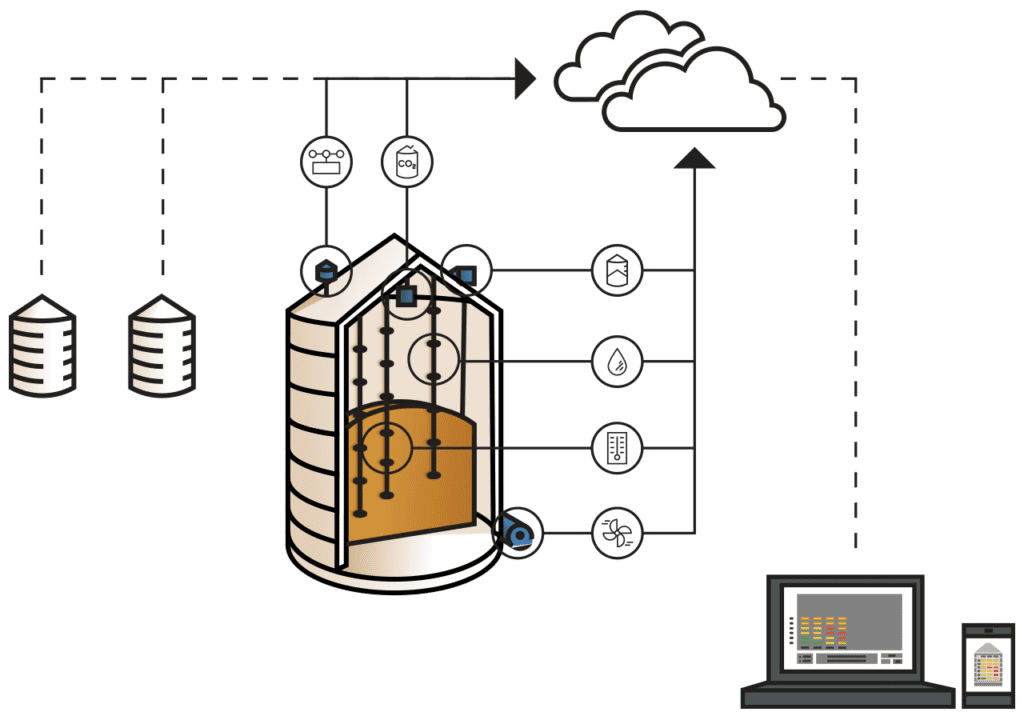

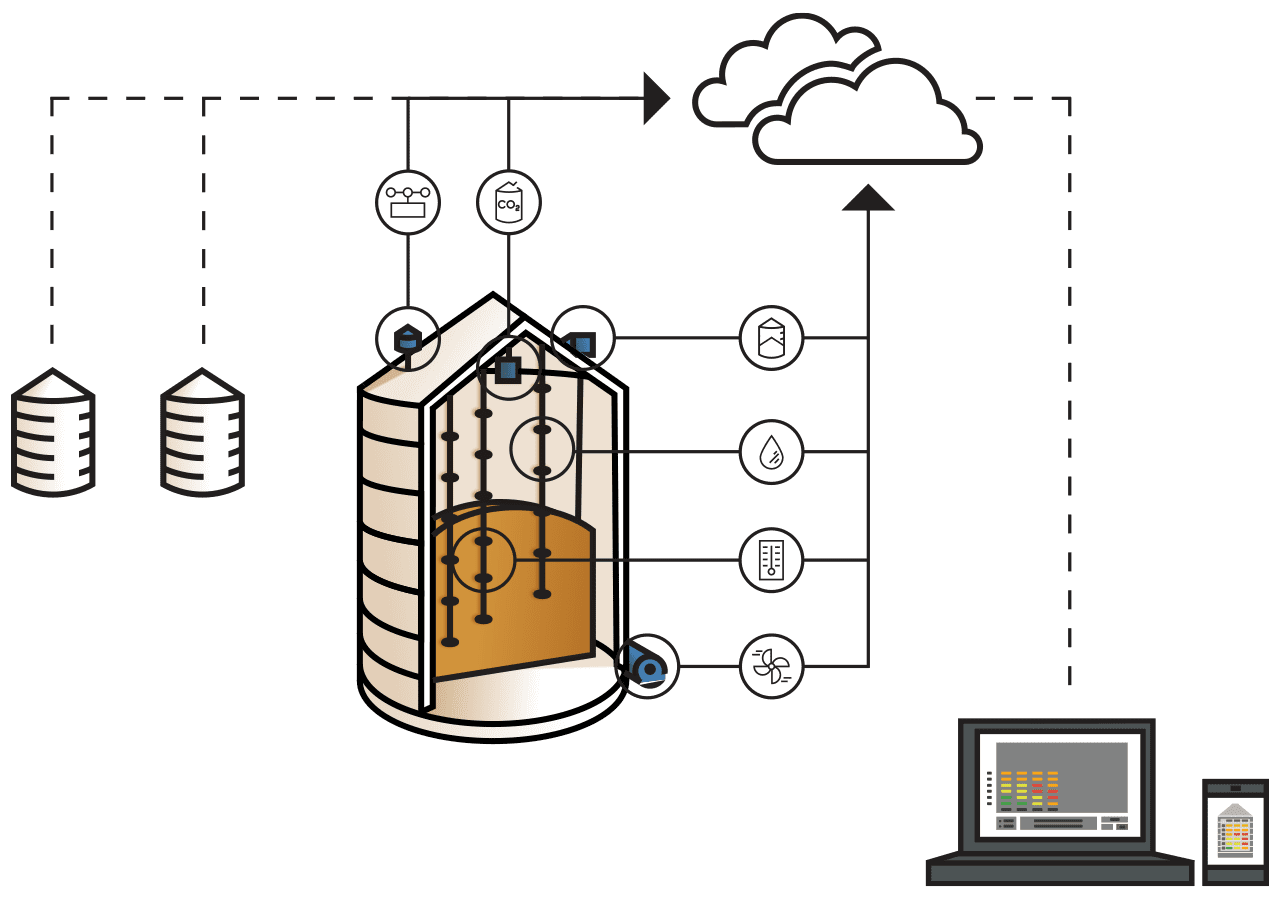

There are a number of ways you can monitor temperatures, including by using a portable device on site or by doing it remotely.

Lower Grain Temperatures at Storage

It’s not enough to monitor the temperature, however. As farmers focus on long-term storage, we also need to lower the temperature of the grain. The old school method has always been to store grain within 10 to 15 degrees of the temperature outside.

On average, the Purdue report says grain temperatures range from 50 to 80 degrees Fahrenheit when put into storage, with some old school farmers believing Mother Nature will cool the grain during the winter. This is something that’s also had to change, as we shift toward a long-range storage mindset.

“Because grain has fairly good insulating qualities, most of the large center mass of grain and air in the bin remains at about the same temperature as it was when placed in storage,” the Purdue report says.

Basically, if you store it at 60 degrees, then it’ll stay at 60 degrees in the center mass. That’s still warm enough for mold and fungus to develop. Also, anything above 55 degrees is warm enough for insects to become active.

By using fans to constantly cool the grain, you can maintain the quality for a much longer period. And the only way to know the temperature in that center mass is with grain temperature monitoring cables.

Frequent Grain Temperature Monitoring

In order to make sure the grain doesn’t rot, it takes more than the occasional checkup. That’s where the biggest change comes in. Most farmers traditionally won’t check their grain temperatures more than once a month, but big changes can occur in that period.

The USDA and Cooperative Extension Service are asking farmers to make grain temperature monitoring a part of their weekly routine. “Check at least every two weeks during the winter,” the Purdue report recommends. “Establish a regular day of the week and time of the day to check grain to avoid forgetting.”

When you check your grain regularly, you can head off small problems before they become big problems. If you discover a hot spot in your grain, it means something is wrong. You can manage your fans to correct the problem and see the grain temperature change in real time. You’ll also be able to check on the temperature change hourly if need be, then promptly shut those fans down.

The simple act of monitoring grain temperatures and doing it on a weekly basis could mean the difference between a rotten crop and a decent profit when it comes time to sell.

We can help make it easier to check grain temperatures and keep grain healthy during long storage times. Together, we can improve your bottom line.

Call us at 800 438 8367, contact us here, or live chat with us to ask about the right grain temperature monitoring system for your new or existing on-farm storage facilities.

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and smart farming.