If all goes as planned, this year will bring another record harvest. Silo temperature monitoring and grain aeration put old silo structures back in the mix for increasing on-farm grain storage.

For years, farmers have utilized silo structures for silage to store grain, both wet and dry. Still over time, farm operations improve, introducing new and improved methods of grain storage. This has left many unused tower silos on farms across the Midwest. Farmers are eyeing old silage silos now, wondering whether they can be used for grain storage, or not. Can these tower silos, once used for haylage, silage, or high moisture grain, be converted for dry grain storage?

The answer is yes, and many farmers have successfully adapted old tower silos for dry grain storage. However, making the conversion presents some challenges. You must consider a handful of factors before adapting old silage silos for dry grain storage.

Factors to Consider When Converting to Dry Grain Storage

A few factors stand out indicating whether or not an existing silo can be updated for dry grain storage. Dry grain exerts more pressure on walls than corn silage. Many older grain silos are not designed to handle the pressure. That means you should carefully examine the conditions of an old silo. You have to make sure that silo walls and reinforcing rods can sustain pressure of dry grain storage.

Some other structural conditions should be considered. The silo should be either hooped or reinforced to properly store dry shelled grain. In addition, the silo requires a roof as well as a concrete floor. Ideally, the concrete floor should reach the height above the surrounding soil grade around the silo.

Walls must allow for moisture and air tight storage. Plus, the silo must have a fill system that minimizes grain damage. It must also have an unload system to withdraw grain from the bottom center. Finally, the silo needs to be in a location that allows for long term grain storage.

Aeration Systems and Temperature Monitoring

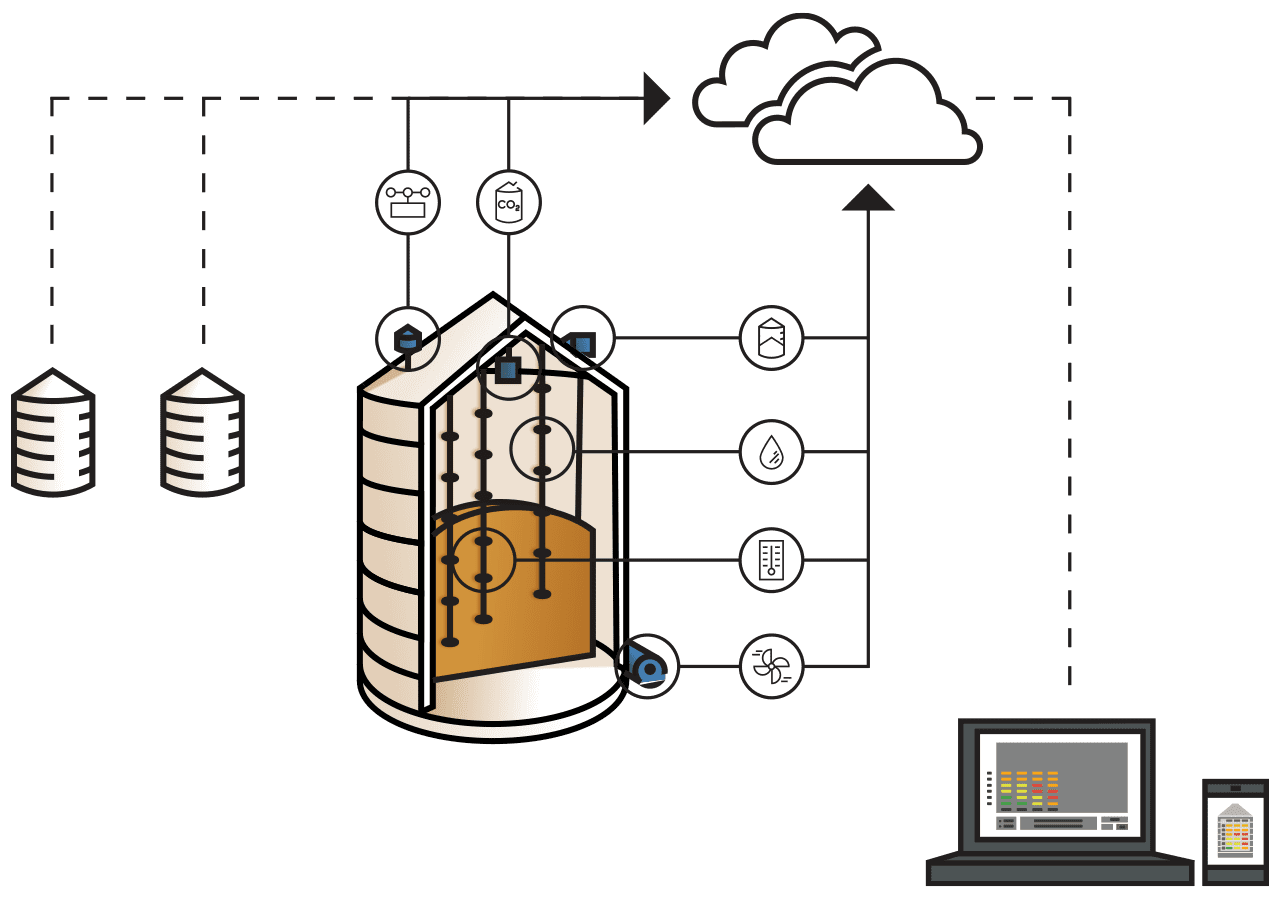

Many factors play a role in successful silage conversion. When storing 2,000 to 3,000 bushels or more of grain, silos must have adequate aeration systems. You have to be able to respond to hot spots with aeration to control temperature and keep grain dry. This is important even if grain is dry when moved into the silo. An aeration system will prevent moisture migration while also reducing mold and insect activity.

Let’s say a farmer stores grain in early October, when grain temperatures can easily reach between 70-90°F or higher. Because grain is a good insulator, the storage center probably won’t change by more than one degree per month. However, colder winter weather will change the the grain located closer to the silo’s outside wall much more rapidly. Outer grain could experience temperatures as low as 10° to 40° F.

The range of temperatures between the inner area of storage and outer grain creates convection air circulation within the grain mass. Cold air along the outer area sinks as warm air in the center rises toward the top of the silo. This convection of air circulation creates moisture as the air warms and rises before cooling at the top. These “hot spots” caused by grain respiration lead to excess moisture, insect infestation, and potential grain spoilage.

Using Temperature Monitoring Cables Makes Repurposing Possible

When looking to convert an old silo, operators should consider investing in temperature grain monitoring systems for silos to prevent convection and grain spoilage. The use of grain monitoring cables have shown even better success rates for repurposing silos for dry grain storage. Silo temperature monitoring in conjunction with aeration prevents spoilage by ensuring the grain storage environment remains optimal.

How Does Grain Monitoring for Silos Work?

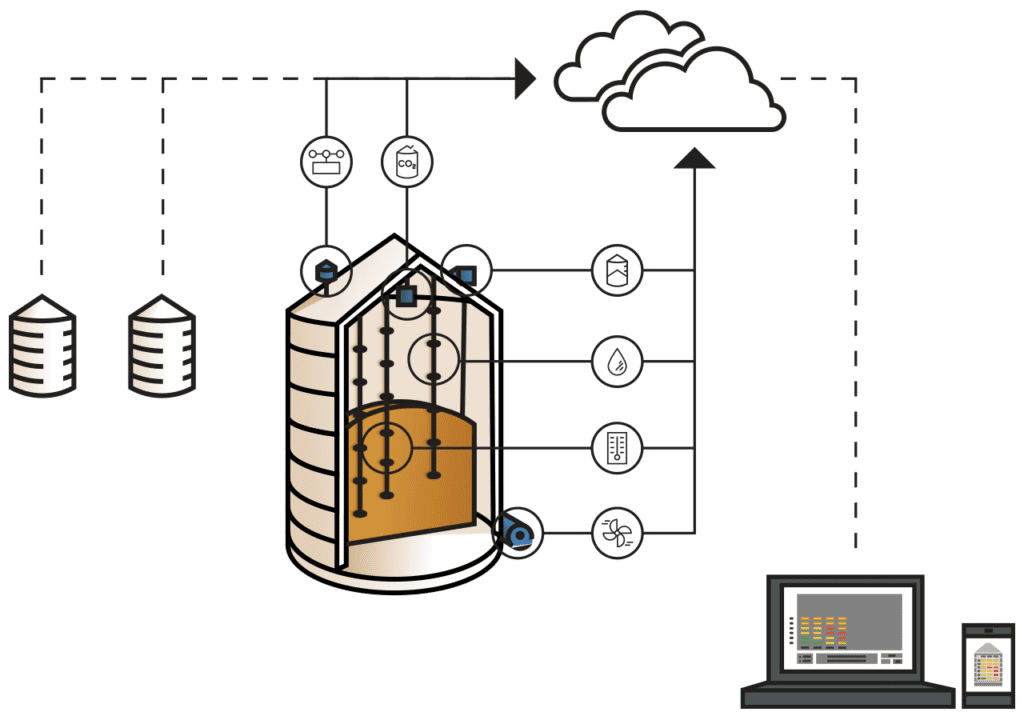

Grain temperature monitoring employs the use of temperature probes hung inside the silos. These probes detect the “hot spots” caused by convection and uneven grain temperatures. The probes alert operators who can then take action to restore optimal conditions for high quality grain and prevent spoilage before it occurs.

Grain monitoring cables like Tri-States Grain Conditioning temperature cables hang from steel or concrete silos and allow operators to efficiently monitor the grain temperature within the silo. Made from durable steel conduit cables and fitted with innovative digital sensors, the cables are thin, yet durable enough to detect temperatures effectively. In addition, the cables do not require any sensor calibration or maintenance.

These cables adapt to a range of silos through well/floor molds in concrete silos, suspension loops in concrete silos or steel bins, as well as pipe socket connections in steel bins. Many manufacturers of silos come equipped with brackets for temperature cables. Operators can also opt for individual set up, if preferred.

Successful Silo Temperature Monitoring

Rather than letting an old tower silo sit unused, it’s possible to repurpose it to store grain at least temporarily. You’ll need to make sure it’s structurally sound and moisture sealed. You’ll also need systems for filling and emptying the silo, an aeration system, and grain temperature monitoring cables. Farmers can successfully store dry grain in tower silos, making it a viable, although not ideal storage option.

Together, we can create successful silo temperature monitoring to add grain storage options on your farm.

Call us at 800 438 8367, contact us here, or live chat with us to ask about the right grain temperature monitoring system for your new or existing on-farm storage facilities.

(Sources: Purdue University and University of Minnesota)

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and smart farming.