Grain storage management is one of the keys to having a successful and profitable year. Since the condition and quality of harvested grain varies annually, each year is different in managing your stored grain. And there’s only one reliable way to know if stored grain is healthy – temperature.

“The quality of stored grain never improves, because the crop has reached maturity,” says TSGC sales manager, Greg Van Sickle. “The only factors that you can control are those that would cause deterioration such as fungus, mold, or insects. By knowing the temperature inside your bin and monitoring it, you can keep the quality of your grain maximum. And you can therefore get your optimum price.”

Corn is more likely to go out of condition when grain temperatures aren’t monitored.

“The only reliable way to know if stored grain is healthy, is by checking the temperature. Each year, more grain goes out of condition due to uncontrolled temperatures than for any other reason.”

How Did Grain Temperature Monitoring Begin?

According to experts at Iowa State University College of Agriculture, “As technology advanced, it became clear that knowing the temperature in a grain bin was the key to understanding whether spoilage was taking place, or not. Anytime any material spoils it gives off heat, and so it changes the temperature of the grain around it.

That was the genesis of the idea, ‘Could we put thermocouples in grain to monitor that?’ If the temperature goes up five degrees in two weeks, something has to be happening. So that’s what created the business of temperature monitoring.”

What about Moisture Migration?

Grain temperature can be used to minimize moisture migration within a bin. Your goal should be to try and keep the temperature within ten to fifteen degrees of the average outdoor temperatures.

“In the fall, you’re going to have the gradual cooling of the bin until you get the grain to the winter temperature that you would like to have it – anywhere from 30 to 40 degrees,” says Van Sickle. Keeping track of this inside/outside temperature ratio is key to avoiding moisture migration.

Inside/Outside temperature ratio is key to preventing moisture migration.

Why Is Regular Grain Temperature Monitoring Important?

Monitoring the temperature of grain on a regular basis gives the grain manager the best chance to make a correction. You’ll notice when a temperature change is occurring, and be able to respond in real time. This speedy action helps preserve the quality of the grain.

Knowing the temperature of the grain also makes it possible to run fans only until the grain is cool. This saves money on utilities. “The big thing on knowing the temperature is the utilization of your fans,” says Van Sickle.

Save money on utilities and avoid grain shrink by knowing when to run fans.

“Nobody wants to run their fans excessively. Besides spending money on the electric company, you’re also losing money to shrink. It’s going out the top of your bin.” Since you get paid on the moisture content and weight, shrink is the invisible thief to avoid.

What Does Experience and Customer Service Mean to You?

Tri-States Grain Conditioning is a well-known supplier of grain temperature monitoring equipment worldwide. Headquartered in America’s heartland since 1982, Tri-States Grain Conditioning makes service and high-quality products their highest priority,” – Jo Winkowitsch, co-owner.

“Customer service is very important. We hear it time and time again from our many customers,” says co-owner Darwin Winkowitsch. They appreciate our quick response to each situation. It matters to busy farmers to get the help they need when they need it. As a family-owned business, we’ve built our international reputation on outstanding service after the sale.

General Manager, Dan Winkowitsch believes serving customers is three pronged – quality products, top service, and the best prices. “Tri-States Grain Conditioning ensures top quality products and top tier service to our customers. We know that we want to provide the best possible products for grain temperature monitoring, and for hazard monitoring. And we want to do that at the best possible price.”

Whether you have a large commercial operation, or a family farm, Tri-States Grain Conditioning has the right products to control energy costs, stop shrinkage, and help protect grain and profits.

Which Temperature Monitoring System is Right for You?

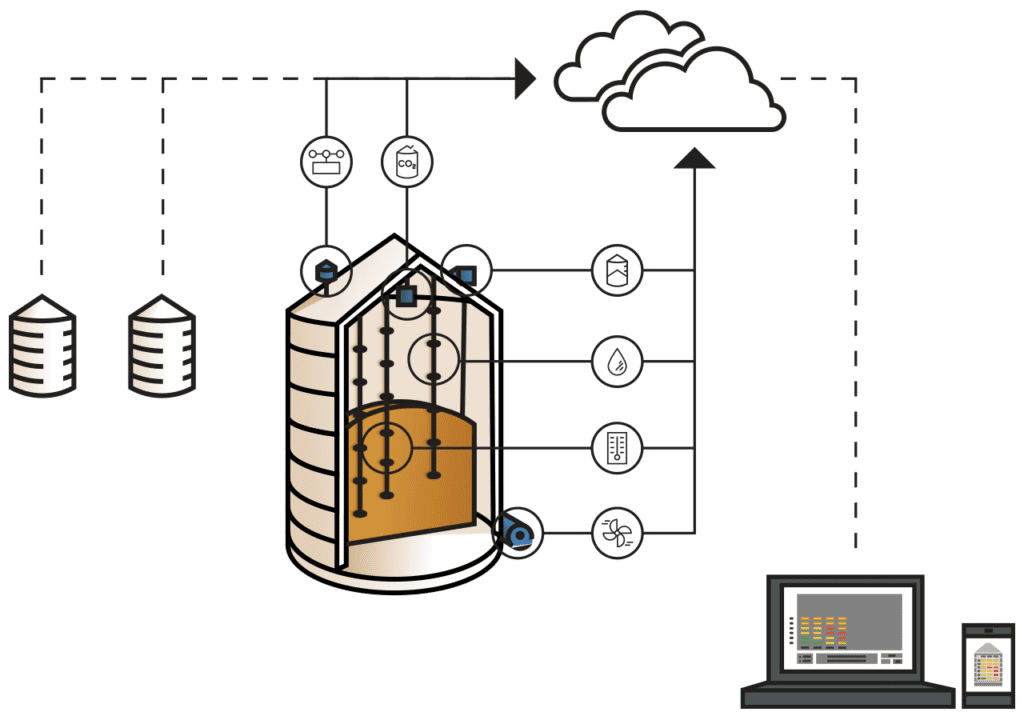

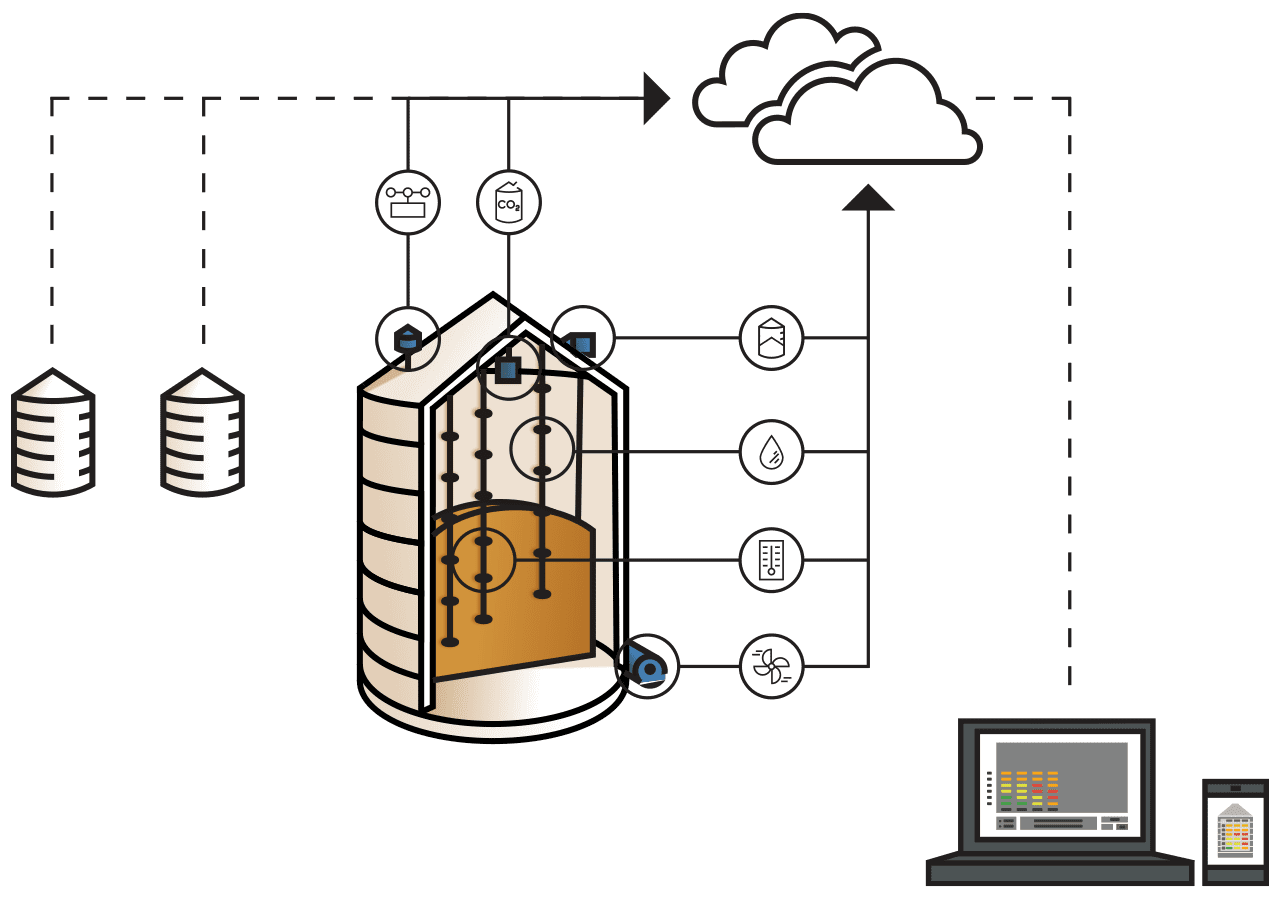

“How Tri-States is trying to help the producer control energy costs, maintain profits, and reduce shrink is by offering a variety of products based on producers’ needs. Tri-States Grain Conditioning’s wireless temperature monitoring systems can monitor grain from one small bin up to multiple silos, flat storage units, and concretes together.

Wireless systems give you the ability to be anywhere on the planet where you have Internet access. You’ll be able to read those temperatures, know what’s going on with your grain, and then make the decisions that are necessary.”

How Does Wireless Grain Temperature Monitoring Work?

Safe Track Wireless System is a complete solution for monitoring commodity temperatures. You can not only see what’s happening to the grain mass that you have stored in your silos, but it’s also going to tell you the volume of grain that you have stored. So, you know what’s happening with it. You know how much you have. And if you’ve entered the information correctly into the system, you know how long each silo has been in storage.”

GrainTrac Wireless System gives you the ability to monitor all your bins on a daily basis without driving, climbing, or keeping hand-written notes. GrainTrac removes the guess work from grain storage.

Dan explains, “GrainTrac is a wireless remote monitoring system that allows you to see what’s happening inside of your bin, again from anywhere you have Internet access. You can access the system from your desktop, or you can check it on your smart phone.

Now once you see what’s going on in there, you have the ability to remotely start and stop fans. GrainTrac removes the guesswork from grain storage, because you know 24 hours a day, seven days a week what temperature your grain is that you have stored. And if you know what the temperature is you know what you need to do with your grain.”

Why Is Portable Grain Temperature Monitoring So Popular?

Tri-States Grain Conditioning’s portable monitoring systems really give you a very economical way to monitor the grain in your bin. You simply plug it into the side of the bin, read it, and jot the data down on a piece of paper. Very simple, very straight forward. Our portable is the most popular, because for the entire system to work you only need a 9-volt battery.

Tri-States Grain Conditioning continues to develop ways to provide accurate and timely data to allow commercial facilities and farm producers to maximize their grain quality in order to produce maximum profits.

What’s the Future of Grain Temperature Monitoring?

The future of Tri-States Grain Conditioning, and the whole industry, is taking a turn from the commercial and moving it onto the family farm. Grain temperature monitoring will move onto those farm structures and those grain bins that have stood there for years, and new ones that are going up.

Grain temperature monitoring moves onto the family farm.

“With our monitoring systems, you can know your grain is good quality. So the day you take it to market, you’re getting maximum dollars for the investment you’ve already had on the farm.”

Let our family help your family have a profitable year. Give us a call, and we’ll walk you through which system is best suited to your operation. You’ll feel secure knowing your grain stays in top condition until you’re ready to go to market.

Call us now at 800 GET TEMP (483 8367) or 712 336 0199. You can also email us for more information about any of our grain temperature monitoring systems at [email protected].

Follow us on Facebook where we discuss a variety of farming topics including grain temperature monitoring and Smart Farming.