It’s easy to ignore grain dust when you’re storing crops. In fact, some farmers may not even think about it at any point. But, that doesn’t mean it’s not a problem.

According to the Centers for Disease Control, inhaling too much grain dust causes grain fever, a chronic respiratory disease where the victim constantly wheezes, coughs, has eye and nose irritation, and has chest tightness similar to a heart attack.

“Grain dust may also induce asthmatic reactions,” the report states, especially in people who easily fall victim to allergies. But if inhaling the dust was the only problem, a self-contained breathing apparatus (SCBA) like firemen use would fix everything. Without proper monitoring though, problems only get bigger.

I’m referring to a grain dust explosion. If the dust builds up to a certain point, one tiny spark causes it to ignite. However, there are ways to protect your grain storage areas from a situation like this. With the right monitoring equipment, you can steer clear of both lung problems and other issues.

Does Grain Dust Commonly Explode?

First off, I need to clarify a couple things. When I say a grain dust explosion, it’s never actually just one. According to this study from Princeton University’s Agriculture Department, the first explosion starts as a small one, creating a pressure wave and igniting a fire.

“The pressure wave moves away from the location of the primary explosion at a speed of about 1000 feet per second,” the report says, “while the fire follows at about 10 feet per second.” Then that pressure builds grain dust into larger concentrations as it pushes forward, creating at least two to three secondary explosions. And before you argue that it won’t happen at your farm, don’t be so sure.

Over the last 10 years, Purdue University says there’s been an annual average of 8.4 grain dust explosions at farms across the Midwest. In 2018, the number jumped to 12.

My point is that this isn’t something you can ignore. The 2019 numbers haven’t been released yet, but from January 2017 to December 2018, six people were killed and 16 injured in grain dust explosions. That also doesn’t count more than $100,000 in damage done to the grain storage sites as a result.

Not only did those farmers have to repair damaged silos, but they also had to find somewhere else to store what was left of the grain. Finding the money and space to build a silo is hard enough when you plan for it in spring. Try doing it in winter as you scramble to save what’s left of your crop.

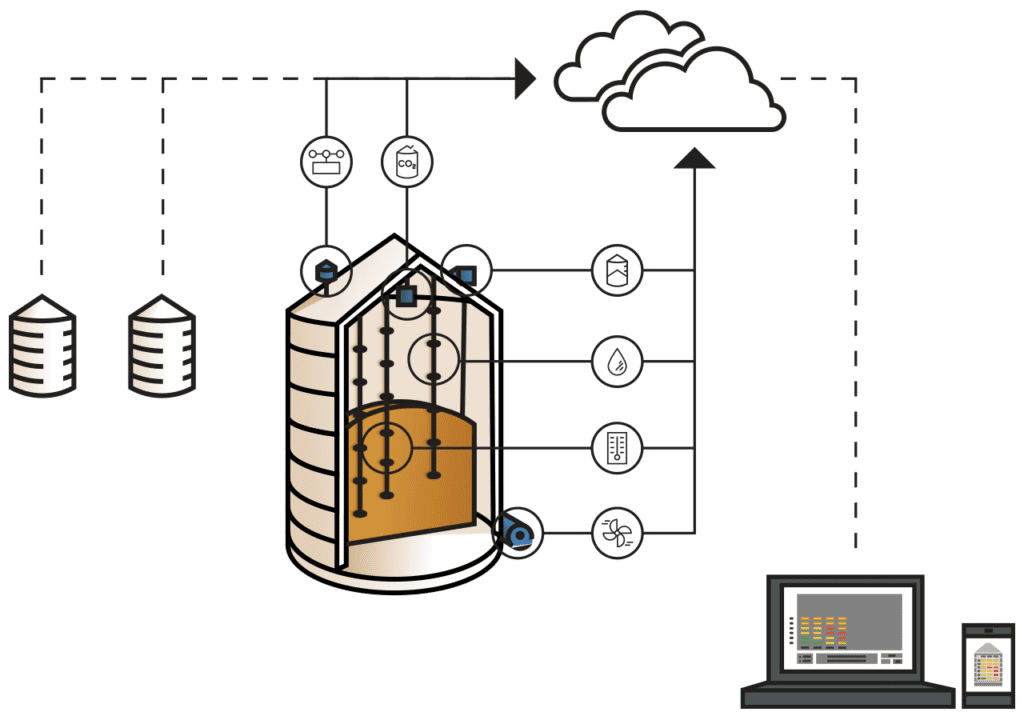

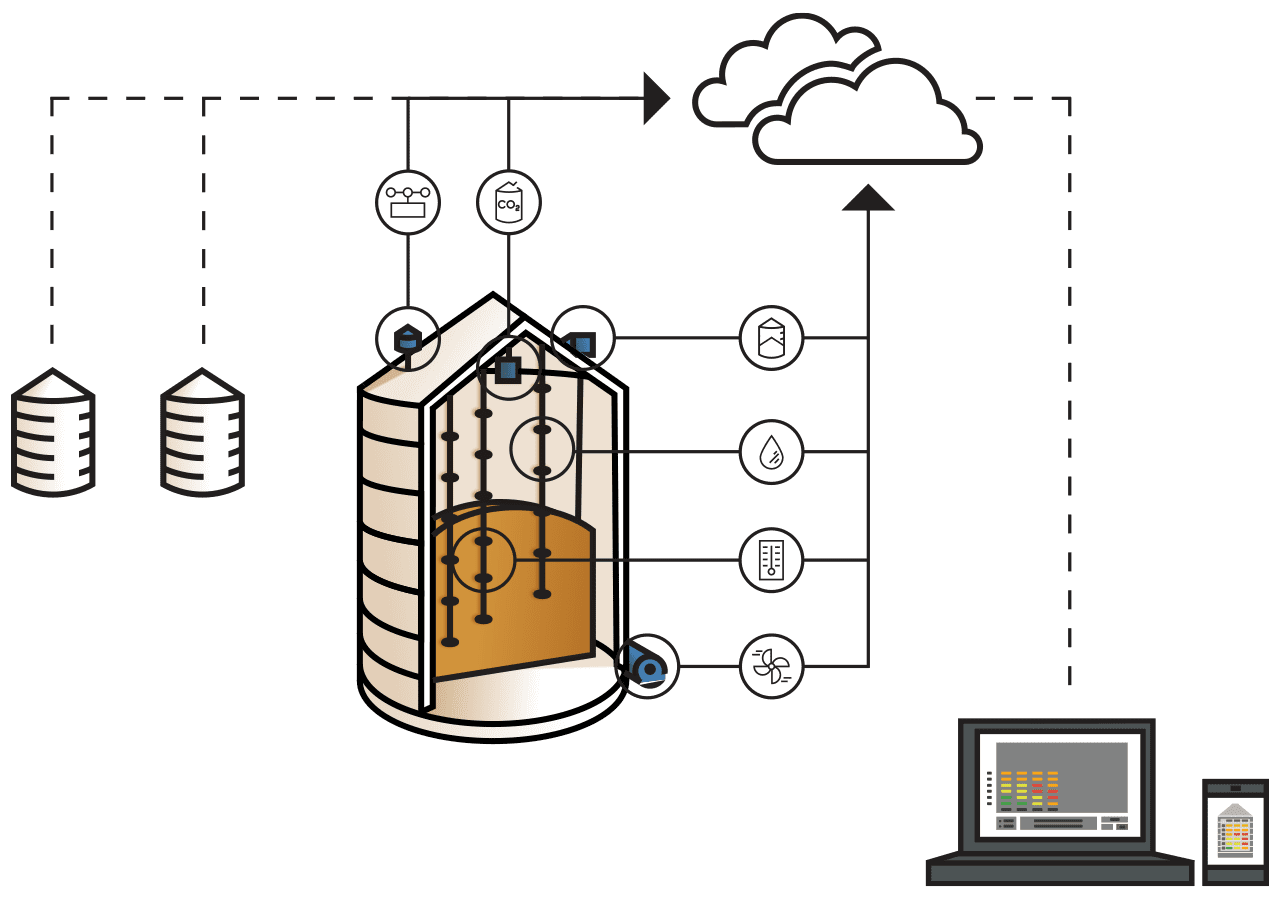

Put A Hazard Monitoring System in Place

You can provide essential protection to grain managers, grain bin facilities, and stored grain by preventing disastrous explosions with a compact, easy-to-use hazard monitoring unit.

What Causes Grain Dust Explosions?

Earlier I mentioned that all it takes is a spark to cause a grain dust explosion. Specifically, this happens at grain transfer points when you’re loading the crop into storage. With all the tumbling, shuffling and general agitation, small dust particles dislodge from the kernels. Sure, you try to sweep it all up, but let’s be honest. How often does that happen?

Instead, it’s not uncommon to walk into a grain storage area and get hit in the face by dust clouds. These clouds tend to be near a hot leg boot section bearing or close to a drag conveyor. If the conveyor malfunctions and sparks, everything could go up. This isn’t a one size fits all situation, however. The size of the explosion depends on the size of the particles.

Wheat, oats and corn, for example, create larger and more explosive particles than sorghum or milo. It’s also not just the grain itself that’s a problem. If you store grain products in your silo, they can cause issues too. That 2019 Purdue University report I mentioned says corn starch is the most volatile and powerful product.

To put it in perspective, a grain dust explosion caused by wheat will likely destroy one room of your silo. An explosion triggered by corn starch, on the other hand, could level the entire building.

A Way to Prevent the Explosions

Fortunately, there are simple and cost-effective ways to prevent explosions from happening.

Remember that spark I mentioned, the one that caused all of this? It’s caused by overheated bearings in a conveyor, or a leg belt rubbing against sidewall casing as a result of misalignment.

Tri-State’s hazard monitoring system immediately notifies a farmer if any of this is happening, giving plenty of time to shut down the equipment and solve the problem. The belt tracker and motion sensors flag a misalignment as soon as it occurs. Able to produce a continuous alarm signal, the equipment comes pre-wired with AWG cable.

It also has adjustable sensibility to eliminate the potential for false alarms and a mechanism set up for testing.

Call Tri-States Grain Conditioning at 1-800-438-8367, contact us here or chat with us to protect yourself and others, as well as your facilities and stored crops from costly and deadly explosions.